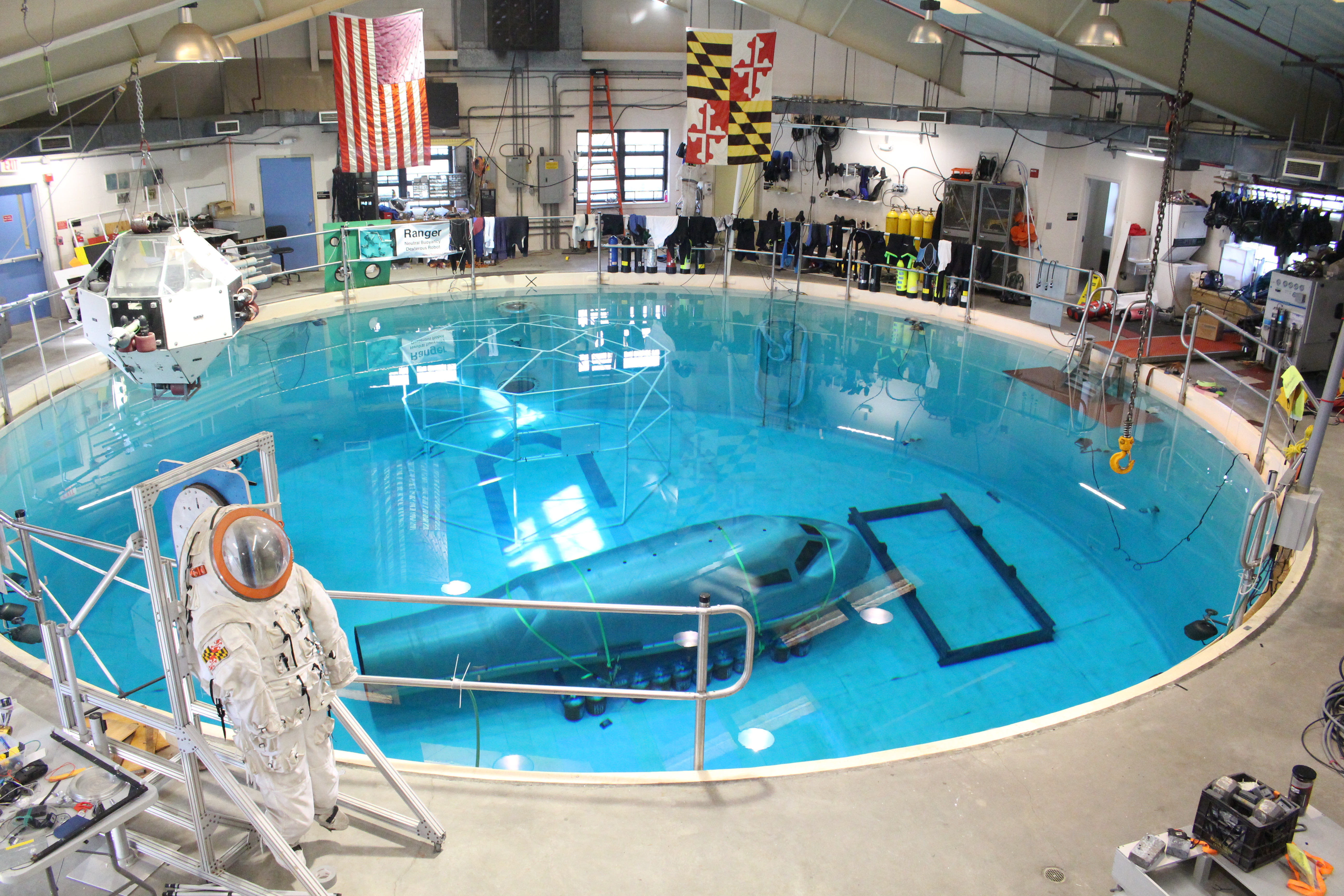

On the University of Maryland campus, there is a pool — 25 feet deep, holding two million pounds of water and able to simulate space’s micro-gravity.

The Neutral Buoyancy Research Facility, located near the campus farm, is designed to simulate the weightlessness of space, and was established almost 24 years ago for that very purpose. It is part of this university’s Department of Aerospace Engineering, and houses the only neutral buoyancy pool on a university campus, said David Akin, the facility’s director. There is one other facility like it in the country, which is run by NASA, Akin said, and only six total in the world.

“It’s very difficult to get microgravity on Earth; in fact, it’s almost impossible,” Akin said. Researchers can adjust the buoyancy levels until objects do not sink or float in the water — just like in the microgravity of space — and measure movement of people, robots, and objects underwater.

The 50-foot-wide pool is filled with 367,000 gallons of regular tap water from the city of College Park. The water then goes through a chemical treatment and filtration process that takes several weeks, Akin said. Any tap water would require the same process, because it needs to be clearer than standard water can get on its own.

The water is kept around 85 degrees year-round to protect the divers from the effects of cold water, Akin said. However, this amount of water kept that warm can have consequences. The air in the facility where the pool is located is always at 100 percent humidity, and it’s virtually impossible to air condition in the summer, he said.

About a dozen undergraduate students and eight graduate students work part-time in the lab.

Justin Kanga, an aerospace engineering graduate student, began working in the lab as an undergraduate engineering student and continues to work there while taking classes.

“We get to do a lot of actual testing and that is a really good experience,” Kanga said. “We’re getting to actually work with hardware. A lot of labs that do what we do [have to] simulate their work.”

A lot of the graduate students are scuba trained, including himself, Kanga said, which will come in handy as a certification in the future.

“I do tell the [students working in the lab] who dive in the water that if they get out of the water and go into the locker room and take a shower, the water they’re washing off in is much dirtier than the water they were just in,” he said.

The facility also has motion capture cameras, the same technology used for filming movies such as Lord of the Rings and Avatar for high-resolution measurements of people or robots moving under the water, Akin said. This is one way to collect data.

The lab has other advantages, Akin noted. One unusual aspect of the lab is the use of robot work alongside humans on projects, as robots are helpful with certain types of tasks and can increase efficiency. The lab also designs and builds space suits so they can conduct research with them.

Christopher Carlsen, a mechanical engineering graduate student who’s been working with the lab since 2008 as a freshman volunteer, now heads most of the engineering design work.

“The students that we have working with us are all very intelligent, and we can go from having a concept or a question about something we did a couple of weeks ago, [to] within an hour or so [having] people on deck, running a full operation,” Carlsen said. “Working that quickly in such a fast-paced environment has been very helpful for us, and it’s very exciting as well.”

Most of the research support has been through NASA, Akin said. They have also worked with the air force, among many other companies. They also work with students to complete projects for a variety of competitions as a way to expand the educational aspects of the lab. They are currently working with eight student projects.

“Working here is the closest you can come to being an astronaut and not have to live in Houston,” Akin said. “It’s very experimental; it’s very hands on.”