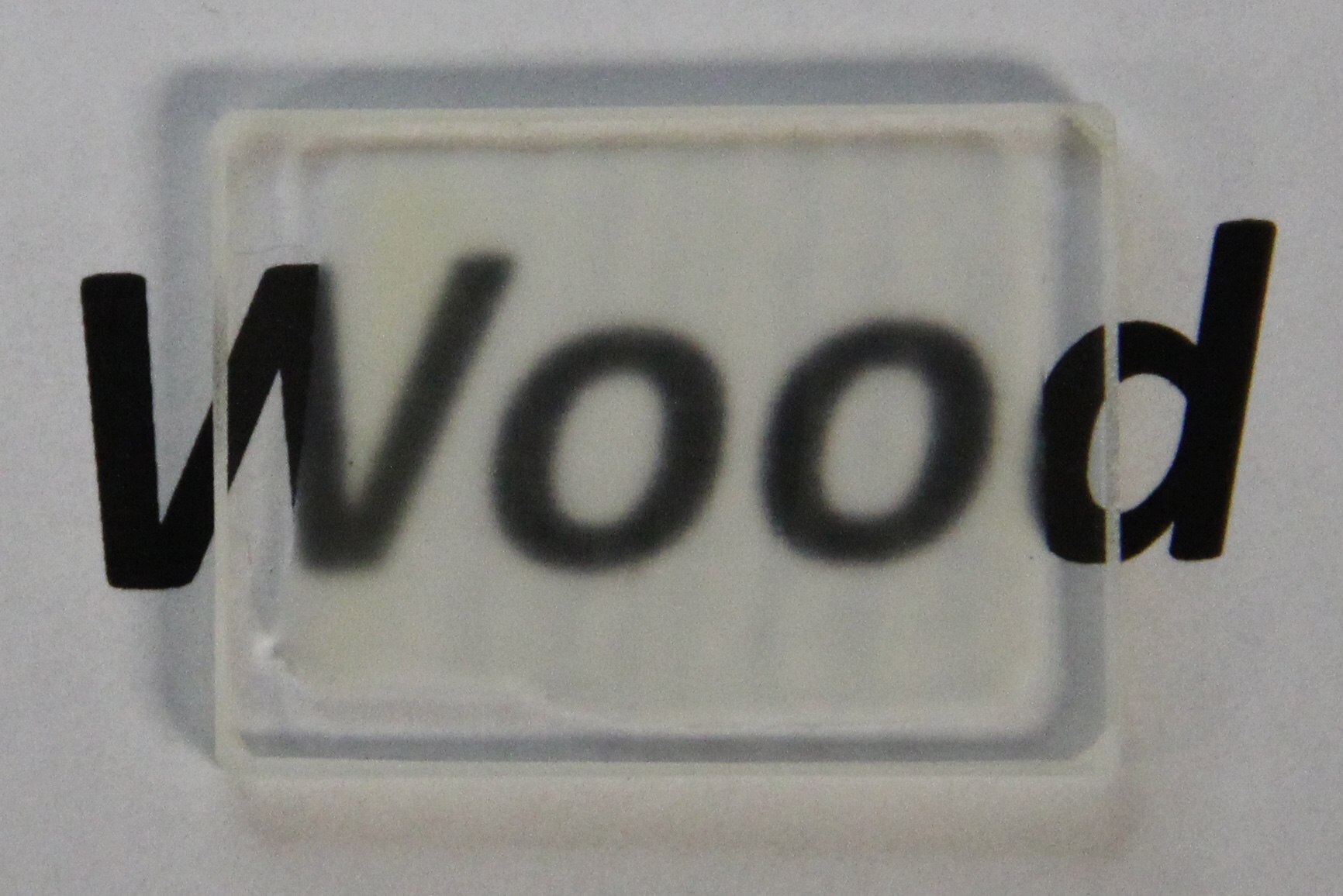

In May 2016, researchers at the University of Maryland developed a new material made from wood that’s transparent like glass.

But on Aug. 11, a second study revealed that this wood can also lower the amount of heat or air conditioning lost within a building due to its “excellent thermal insulation.”

The material, created by removing the wood’s coloring and adding epoxy to strengthen it, has several properties that show promise for use in windows, said Tian Li, an author of the study. Li worked with nine other authors, ranging from faculty in the department of materials science and engineering and the department of mechanical engineering, to researchers in the Energy Research Center.

First, the transparent wood has “very good light management,” Li said, “and can be used to guide sunlight into the house and distribute it very efficiently.”

The material has up to 90 percent of the transparency of glass, and it’s also better at resisting impact, according to the first report, published in May.

“If you hit the glass with the hammer, it shatters, but the wood has a much better [ability] to absorb energy,” Li said.

The material is advantageous — it allows light into a room but protects against heat loss because it’s a better insulator than glass, said Eric Wachsman, the director of this university’s Energy Research Center.

Researchers took pictures of the wood in the university’s Advanced Imaging and Microscopy Lab, where materials can be photographed at a very close range, said Sz-Chian Liou, a research associate and electron microscopist with the lab. This image formation is similar to that of optical microscopes but uses a different source to make the image, he said.

Rather than using microscopes that focus on a subject with light, the lab used electron microscopes, which use beams of electrons, to magnify materials at a high resolution.

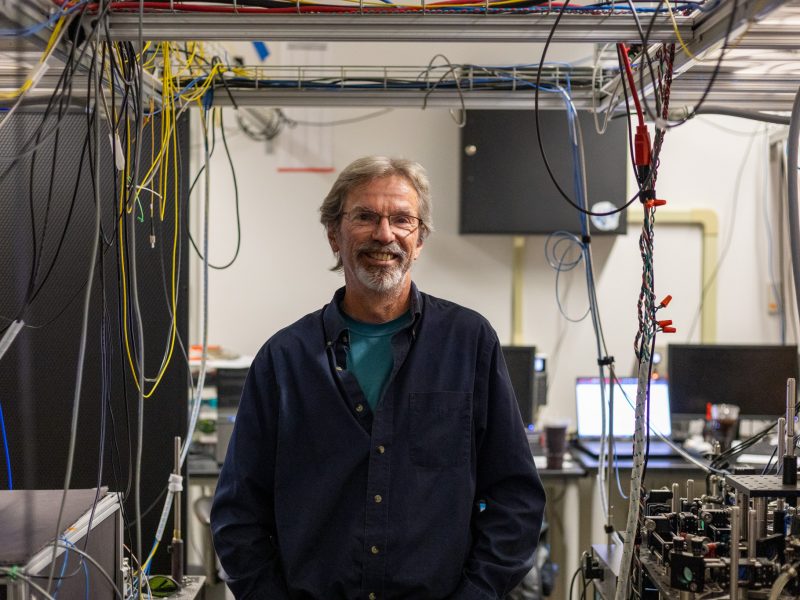

“All of those materials have properties that … are related to the microstructure,” said Wen-An Chiou, director of the lab. “People want to study [them] because they want to know the properties.”

That’s why researchers use electron microscopes — they get a much closer view of the material itself, all the way down to the atom, Chiou said.

So far, the material has only been tested on a small scale using blocks of wood that were up to five inches in diameter. For a portion of their testing, they created a tiny model house to analyze the insulation properties of the material and used this model to determine the improved insulation property of the material.

The next step, Li said, is to enlarge the size of the wood for more testing. In theory, this material could become the new standard for windows, but it will be several years before the research reaches that point, she said.