With 50 3-D printers softly whirring behind her, Provost Mary Ann Rankin launched the MakerBot Innovation Center yesterday, using scissors created by one of the machines to perform the ribbon-cutting ceremony.

The innovation center, located in the Technology Advancement Program Building and sponsored by the engineering school, is the sixth of its kind in the world and the first in a Big Ten university.

“This exemplifies what’s happening all across our campus — in the libraries, in the arts department, everywhere,” Rankin said. “People are thinking in terms of new ways to create and see and manipulate and just do innovation that’s transformative. … I’m so proud of Maryland for being at the front of this.”

Starting yesterday afternoon, students across all departments gained access to the printers in the center, which can be accessed by logging on to terrapinworks.umd.edu. Students submit their project plans on the website and then come pick them up at the innovation center when ready.

“Everyone should learn about design, not just engineering students,” said Darryll Pines, the engineering school dean. “Whether they’re in arts and humanities or social science, this facility will give them creativity and spirit to innovate and create anything they want to. Every student, every person, has an idea and we want to empower them to do it.”

The MakerBot Innovation Center cost about $300,000, according to Jim Zahniser, the engineering information technology executive director, and using the printers will cost students 10 cents per gram of product.

“Sometimes you have these cool ideas, but you can’t prototype them because of the cost,” said sophomore computer engineering major Brunel Fangmo, who used a 3-D printer to build part of a hovercraft. “Having them here makes it so easy and accessible.”

So far, the printers have been used to create bracelets, a working ukulele and multiple Testudo statuettes.

But the potential for 3-D printing extends beyond trinkets to vascular grafts or car and robot parts.

“I don’t even think we can foresee what the educational impact will be,” Rankin said. “This has so many applications. Everything you think of — if you just put your mind to it — you can create it and hold it in your hand. It’s really limitless.”

Starting this fall, freshmen entering the engineering school will use the innovation center during their required introductory course, ENES100: Introduction to Engineering Design. Last fall, about 700 students in the class had to work with 10 3-D printers.

“That didn’t really seem scalable,” Zahniser said.

The engineering school now has access to 75 devices, which can print anything from plastic to biomaterials.

The innovation center has been in “quiet mode” for three weeks, Zahniser said, and students are already getting use out of it.

Fadel Muci, a senior mechanical engineering major, is using the printers for his capstone project, in which he’s building a water-efficient showerhead. He’s using three printers for different parts of the project, as each takes between 27 and 44 hours to complete a piece of the device.

“Without printers like this, it wouldn’t be possible,” he said. “We’d have to make it in China and it’d cost a lot of money. Just the molding would probably cost $800.”

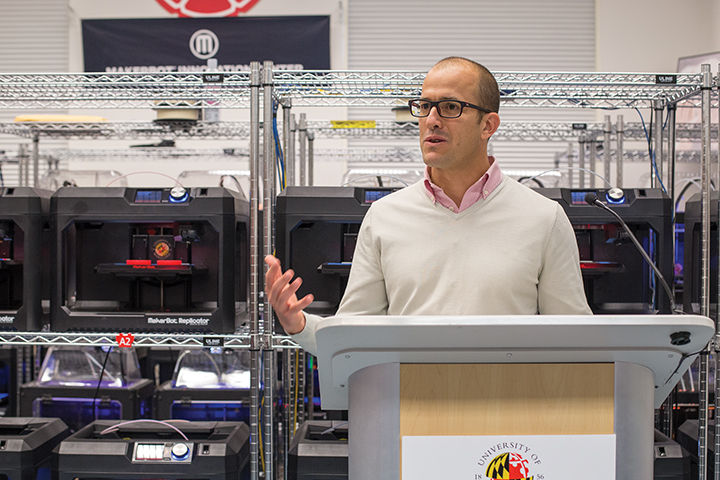

Given the progress already made, Jonathan Jaglom, MakerBot’s CEO, said he looks forward to seeing what comes out of the innovation center in the future.

“Through this innovation center, definitely we’re going to see some great ideas come to fruition,” he said. “I’m excited to see what happens in three years, five years, even two years, to see how far it goes. As students learn how to use this technology and think more creativity, we will see great ideas come to light.”

Rankin said she can’t wait to use it herself.

“Of course, I don’t know how,” she said, “but I’d love to learn.”

Jonathan Jaglom, CEO of MakerBot, speaks at the opening of the MakerBot Innovation center in the Technology Advancement Building on Thursday, April 23. The center is a large-scale 3-D printing center available to all students for designing and printing innovations.

Various 3-D printed objects are displayed at the opening of the MakerBot Innovation center in the Technology Advancement Building on Thursday, April 23. The center is a large-scale 3-D printing center available to all students for designing and printing innovations.